Live OEE |

||

| This site is a portal for our clients to login to the OEE Software to view their live production line data, overall factory effectiveness & history reports specific to the factory, production line, product, operator, processes and more. | ||

Our Head Offices are based in New Zealand & South Africa but our system can be used anywhere in the world and is very easy to setup yourself. If you would like a free onsite demonstration go to our contact page HERE and send us an email so we can arrange to demonstrate this system on one of your production lines. Or else you can have a look at our demo factory by logging in with: Username: demo | Password: demo Products That We Offer |

||

Operator Console

|

||

Product Counter

|

||

Local Server

|

||

Visual Display Box

|

||

WiFi Range Extender

|

||

| To purchase these products please contact us directly. Please note that the Product Counters incur a monthly fee for the license to use them within our system and for the following online package that enables all history records to be backed up on multiple secure servers with unlimited disk-space & unlimited bandwidth. The monthly fee is priced as follows:

1 – 2 Product Counters is $80 ea p/m 3 – 4 Product Counters is $70 ea p/m 5 – 9 Product Counters is $60 ea p/m 10-19 Product Counters is $50 ea p/m 20- ∞ Product Counters is $30 ea p/m

All OEE Software Products Communicate via WiFi |

||

View OEE From Your Office, Board Room or Factory Floor

|

||

| Existing/New Tvs or Projectors may be used to display live details! | ||

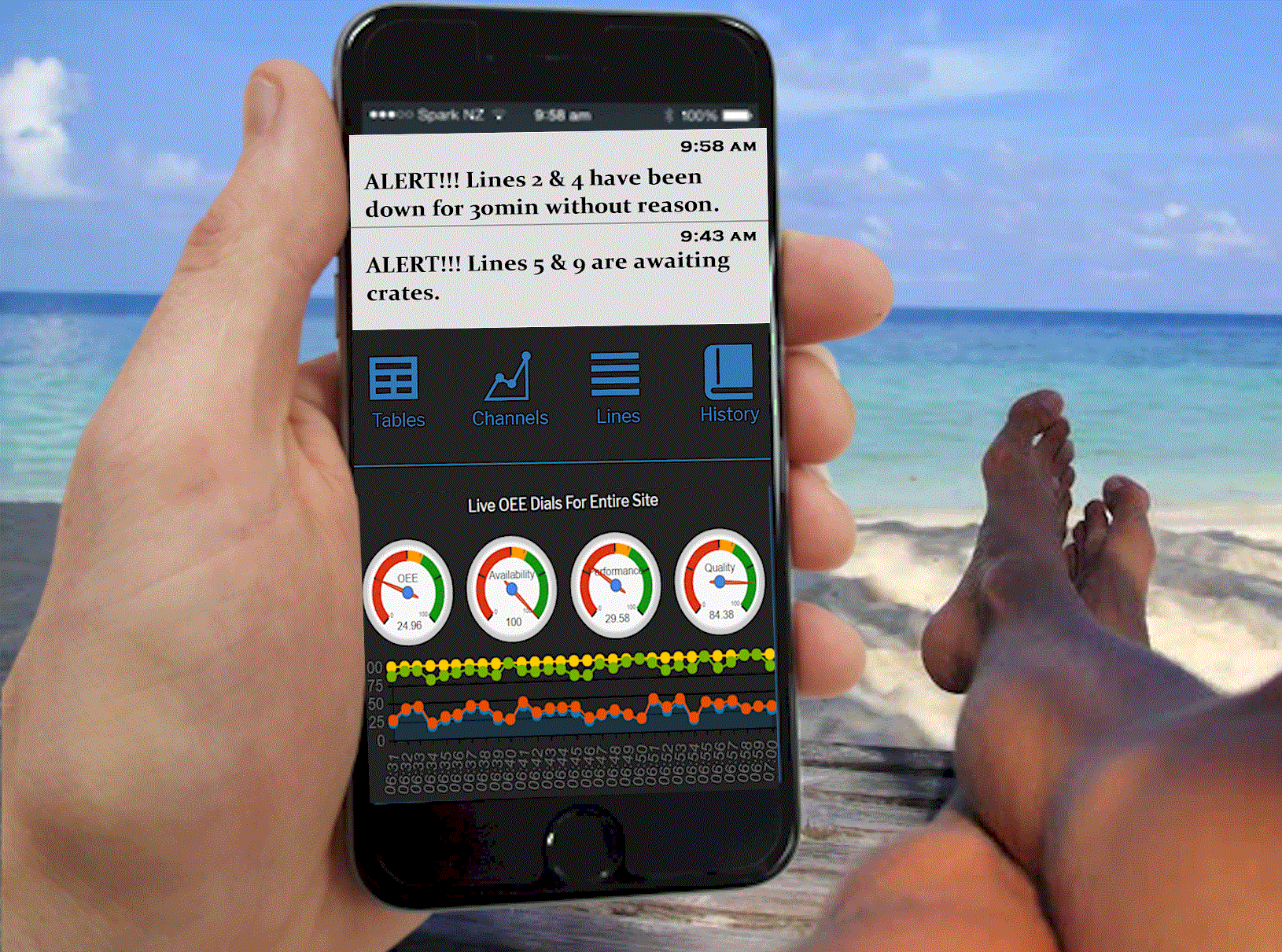

Stay In Control Even When You Not Onsite

|

||

| This system works on ALL platforms!! | ||

System Overview

|

||

Why OEEWhen manufacturing companies run up against capacity problems today, they immediately look to increase overtime, add shifts, or purchase new equipment. Instead they should look to optimize the performance of their existing machines to increase equipment reliability, minimize changeover times, improve operator performance, and lower overall downtime. All these investments can be made to increase capacity and will pay greater dividends by allowing a manufacturing plant to spend its valuable time and money on their manufacturing process instead of new machine purchases. “How can we optimize the performance of their existing equipment?”The answer is Overall Equipment Effectiveness (OEE). Live OEE is an effective tool to benchmark, analyze, and improve your production process. This OEE Software System gives you the ability to measure your machines for productivity improvements. OEE not only measures these inefficiencies but groups them into three categories to help you analyze the machine and have a better understanding of the manufacturing process.

Putting this system in place to address these concerns and improve the manufacturing process can be very time consuming and costly. Live OEE allows the whole plant to be involved in the process of improving OEE. From the machine operator to the production manager to the plant manager, this production monitoring solution visualizes information that can help everyone recommend solutions. The bottom line for all employees should be to reduce production losses and build profitable products. The Live OEE Software provides production managers and machine operators with the necessary real time information to make crucial decisions about the effectiveness of the production process. Machine operators get a first hand look at the production process and the key information of the machine by viewing the data on the Console OEE Software. Instead of manually recording this data for end of shift results, the machine operator can monitor, analyze, and improve their process in real time throughout the day. A truly comprehensive OEE Software solution will provide machine operators and production managers with continual line notification and control so that actions can be taken to prevent events that can result in downtime, slower cycle speeds, and poor product quality. This system should also provide a way for operators to capture codes or comments about the production process to review and analyze later during root cause analysis meetings. The OEE Software provides all these features to help implement a OEE solution. Measuring the inefficiencies of your machine operators and equipment can yield significant results for your company. With no software to install and the data source formulas programmed into the Live OEE System, all you have to do is select the functionality of the application from drop down menus. You install the inputs, select the data sources and the Live OEE Software will take care of the rest. |

This device is water resistant! You will need a minimum of 1 Product Counter on each production line. If you have 2 Product Counters on each line then Quality is automatically calculated. If this is not currently feasible then operators will need to manually input discarded products into the Operator Console. You can always upgrade later on. Product Counters Even Have Built In Range Extenders To Increase WiFi Coverage.

This device is water resistant! You will need a minimum of 1 Product Counter on each production line. If you have 2 Product Counters on each line then Quality is automatically calculated. If this is not currently feasible then operators will need to manually input discarded products into the Operator Console. You can always upgrade later on. Product Counters Even Have Built In Range Extenders To Increase WiFi Coverage. If you have a poor unreliable internet connection then a local server is strongly recommended as an optional extra. Even if you have a good internet connection it is better to have a local server because the entire system will be able to run faster and more reliably.

If you have a poor unreliable internet connection then a local server is strongly recommended as an optional extra. Even if you have a good internet connection it is better to have a local server because the entire system will be able to run faster and more reliably. Lets say you already have a TV or projector in your boardroom or factory(within WiFi signal), just plug this USB into the USB port(this powers the device) and then plug the HDMI into the HDMI port and now you will have a live visual display. If you want this at home or on another premises then ask us for the Online Visual Display Box. These devices are water resistant!

Lets say you already have a TV or projector in your boardroom or factory(within WiFi signal), just plug this USB into the USB port(this powers the device) and then plug the HDMI into the HDMI port and now you will have a live visual display. If you want this at home or on another premises then ask us for the Online Visual Display Box. These devices are water resistant! Nighthawk Dual-Band Gigabit Wi-Fi Range Extender enables you to extend the wireless signal between devices by up to 10,000 sq. ft. with speeds up to 1900 Mbps. Product Counters have built in range extenders so it is possible that you might not need this device however you cant use your own WiFi extender as the entire system is in a closed secure network. This device is shipped with correct network security to allow you to extend you signal by simply plugging it in.

Nighthawk Dual-Band Gigabit Wi-Fi Range Extender enables you to extend the wireless signal between devices by up to 10,000 sq. ft. with speeds up to 1900 Mbps. Product Counters have built in range extenders so it is possible that you might not need this device however you cant use your own WiFi extender as the entire system is in a closed secure network. This device is shipped with correct network security to allow you to extend you signal by simply plugging it in.